At the heart of our company lies our encapsulating statement: Right People, Right Ideas. This powerful statement sets a high bar for our team and shapes our values and approach to every project we undertake. Our Star Value Program reflects this ethos, as it guides us in how we strive to be the right people with the right ideas for each of our clients. For almost thirty years, we’ve honed and perfected our program, implementing it in a wide variety of industries, including some of the biggest names in Aviation, Bio-Tech, and Pharmaceuticals. Our experience and expertise allow us to deliver tailored solutions that meet the unique needs of each client we serve.

MS. Carita label and graphics manufacturing

As a Labels and Graphics manufacturer, we know and understand how important labels and product identification components are to marketing, product function, and corporate branding. Assisting Engineering on the front end with the right solutions and working with Purchasing to achieve strategic objectives is why we are here. Our goal and objectives include:

- Establishing Standardized Pricing on Repetitive Items

- Reducing Inventory both In-House and at the Supplier

- Lower Unit Costs / Improve PPV Performance

- Exploration of New Technologies

- Reduce Transaction Processing Costs

- Link Your Engineering with our Art Department Professionals

- Provide VMI Support / Distribution and Fulfillment

That’s a good list to write down in a quick blog but the common question is “How?”. Our Star-Value Program is our answer. Through this program, we aim to provide quality technical expertise and cost reduction opportunities by exceeding procurement objectives. Over the course of the next several weeks, we will be diving into this program and its details. We might even meet some folks from the team who assist existing and potential customers through this process. But for now, let’s get an overview of what the Star Value Program includes.

Mass printing labels for workplace

Star-Value Philosophy

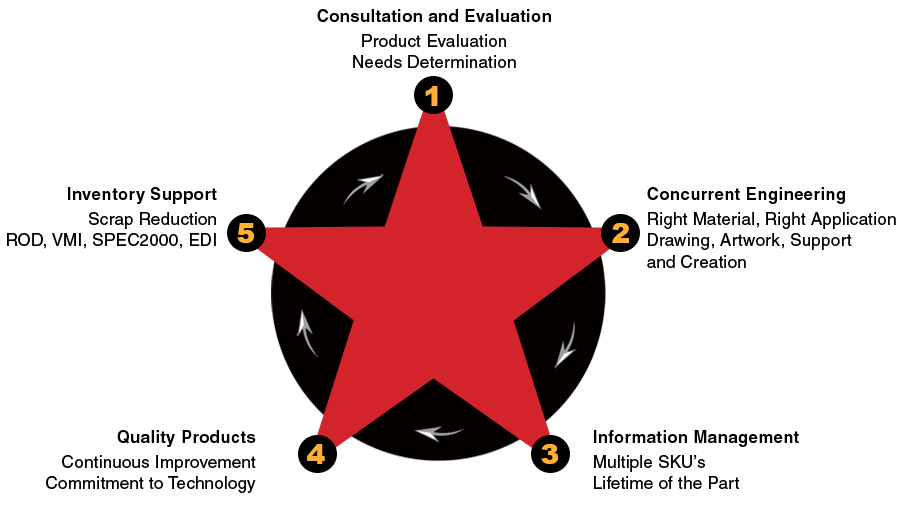

Just like the five points of a star – The Star Value Program has five steps to ensure customers get the right product for the right job. These five areas are Consulting and Evaluation, Concurrent Engineering, Information Management, Quality Products, and Inventory Support. Using these steps, we not only get the customer what they need but also help the customer lower their costs and reduce waste.

Step 1: Consulting and Evaluation – Our team is here to help and assist with product evaluation and needs determination. Our goal is to come alongside purchasing agents, product engineers, and NPI product managers to assist with their objectives. During this process we look at the scope of your current Label and Graphic requirements, identify opportunities for Production optimization with same size, product / material bundling and forecasts to maximize value engineering opportunities that reduces both hard and soft costs.

Step 2: Concurrent Engineering – Choosing the right materials for the right application is especially important. If this step is skipped or missed, product failure can occur in the field which can be costly for all parties. To reduce this risk, our teams work together in identifying the right material, production process and provide drawing, and artwork support.

Step 3: Information Management – MSC manages 1, 10, 100, or a 1,000 part-numbers for our customers. MSC accomplishes this through utilization of sound methods and technology to manage: revisions, changes, drawings, art-files, and shipping information. Our ERP / MIS system allows for data integrity and the information management process to develop at the beginning of a project and information is maintained throughout the life cycle of your label, graphic and product identification component.

Step 4: Quality Products – At MSC, quality is the core-value of everything we do. Managed by everyone in the organization from line personnel to the President. STAR-VALUE quality teams review, analyze and put into place corrective actions and eliminate revenue leaks with-in the organization that hinder progress and quality of parts shipped to our customers. Various component labeling and graphic systems have been tested and are recognized by Underwriters Laboratories.

We continuously strive to stay up to date with the latest technologies and methods to ensure our clients receive the best product and service possible. Our Quality Statement Objective says it all:

We will deliver defect free products on time to our customers.

Step 5: Inventory Support – Our STAR-VALUE Program has repetitively demonstrated that an inventory program can be tailored to meet your needs, whether min/max, fulfillment, distribution or kanban, Stock Keeping Units can be improved and managed with our assistance to minimize waste and reduce on-hand inventory to lower carrying costs.

Conclusion

Ms Carita’s commitment to STAR-VALUE: Evaluation, Concurrent Engineering, Information Management, Quality Manufacturing, and Inventory Management, provides our customers the opportunity to align with a single-source label and product identification component provider resulting in substantial soft and hard cost savings that will improve your bottom-line.

Just a reminder – our Scope of Manufacturing includes:

- Digital Imaging: Decals, MarCom, Internal Graphics, Labels

- Flexography: High Volume Labels, 7 Color

- Screen Printing: Decals, Graphic Front Panel Overlays, Floor Graphics, Labels

- Bar-Coding: Identification, Serialized Labels

- Embossing: 3D, Durable Panel Overlays

- Laser Cutting: Prototype, Fast Turn, No Tool, Low Volume

- Die Cutting: Tool, Mid-High Volume

- Laminating: Protection and Application

Contact Us Today to Learn More – Our staff is here to assist.

1 (925) 243-1720

Ms. Carita Inc. Team – The Right People with the Right Ideas.